Decathlon Introduces Circular Logistics Model to Cut Emissions and Waste

LILLE – July 2, 2025

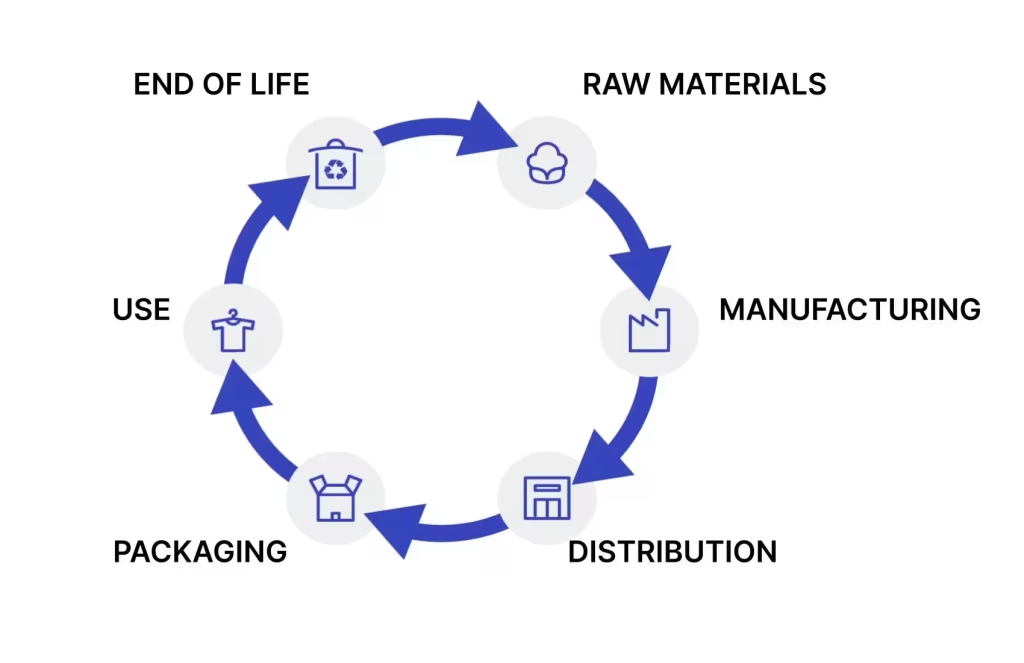

The French sporting goods retailer Decathlon has officially launched a new circular logistics program aimed at transforming how products move through its supply chain — and how they return.

Unveiled Tuesday at its regional logistics headquarters in Lille, the program is designed to reduce carbon emissions, minimize waste, and recover materials through a fully integrated system of collection, reuse, and short-distance redistribution.

“This isn’t just about lowering our carbon footprint,” explained Thierry Leblanc, the company’s Head of Supply Chain Innovation. “It’s about building a system that treats every product and every package as a resource — even after it leaves our stores.”

Reversing the Flow: How It Operates

At the heart of this shift is a reverse logistics network that collects used packaging and returned merchandise from Decathlon stores and customers. These are sent back to urban hubs, where materials are sorted, cleaned, and repackaged for reuse.

Three cities — Lille, Lyon, and Brussels — currently host these hubs. Each site operates with solar-powered infrastructure, and deliveries between hubs and major warehouses are made by rail, in partnership with SNCF Fret.

In trial runs earlier this year, Decathlon recorded a 43% drop in carbon emissions per parcel, without increasing delivery times. The results, according to the company, show that sustainability can be scaled without sacrificing efficiency.

A Focus on Materials, Not Just CO₂

The project, named CycloChain, does more than cut emissions. It’s also targeting material waste. Over 1.4 million cardboard packages and 600 tons of plastic have already been recovered and reintroduced into the system since March.

Customers returning goods are offered incentives: store credits for worn equipment, or discounts when opting for reused packaging. Decathlon reports that one in ten customers is now choosing second-hand gear over new — a shift the company wants to encourage.

“We’re seeing clear signals that consumers value transparency and reuse. If logistics can support that behavior, it becomes a long-term advantage,” added Leblanc.

Sector Reactions and Next Steps

Industry experts are paying close attention. EchoTrack, a European monitoring group for sustainable logistics, has labeled CycloChain “a benchmark project” for closed-loop supply systems in the non-food retail sector.

Retailers across Europe, including Leroy Merlin and Decathlon’s direct competitor Intersport, are reportedly exploring similar models after visiting the pilot sites.

The company plans to publish its first full-cycle impact report this autumn and has pledged to share its packaging reuse standards with other companies — a rare move in a sector still tightly guarded over logistics operations.

The post Decathlon Introduces Circular Logistics Model to Cut Emissions and Waste appeared first on The Logistic News.

Share this post

Related

Posts

Finland warns of probable attempts to sabotage underwater infrastructure

Finland is raising its voice on a subject that has become critical for Europe: the vulnerability of cables, telecom links,...

Exports are still progressing, but the decline toward the United States is worrying

Japan records a fourth consecutive month of export growth, driven by solid demand in certain technological segments. But behind this...

The value of engines boosts teardowns and strains the freighter chain.

Engines are sometimes worth more than the plane: “teardowns” are accelerating and the freighter conversion chain is tightening Context: Engines...

Data becomes the strategic weapon of shipping in 2026

The digital transformation of the maritime sector is reaching a turning point: by 2026, data will no longer be a...